Chemical Inventory

Chemical Inventory Management: A Comprehensive Guide for Optimal Safety and Efficiency

Chemical inventory management is a critical aspect of any laboratory, research facility, or industrial setting that handles a wide range of substances. Proper management ensures the safety of personnel, maintains regulatory compliance, and optimizes operational efficiency. In this comprehensive guide, we delve into the intricacies of chemical inventory management, offering expert insights and practical strategies to enhance your organization's practices.

Understanding the Importance of Chemical Inventory

Chemical inventories are vital for numerous reasons, each contributing to the overall success and safety of an organization. From regulatory compliance to efficient resource allocation, a well-managed chemical inventory offers a plethora of benefits.

Firstly, proper chemical inventory management ensures adherence to strict regulations governing the use, storage, and disposal of hazardous substances. These regulations, often enforced by government agencies, aim to protect both the environment and human health. Non-compliance can lead to severe penalties and legal consequences, highlighting the critical nature of accurate inventory tracking.

Secondly, an efficient chemical inventory system enables better control over resources. By keeping an updated record of chemicals, organizations can avoid over-purchasing, minimize waste, and optimize the use of expensive or specialized substances. This not only reduces costs but also promotes sustainability by minimizing the environmental impact of excess chemical disposal.

Furthermore, a well-organized inventory facilitates research and experimentation. Scientists and researchers can quickly locate the chemicals they need, saving valuable time and effort. This streamlined process enhances productivity and fosters an environment conducive to innovation and discovery.

Lastly, effective inventory management plays a crucial role in emergency response planning. In the event of a chemical spill or accident, an up-to-date inventory allows for swift and accurate assessment of the situation, aiding in the formulation of an effective response strategy. This proactive approach is essential for minimizing the impact of such incidents and protecting the health and safety of personnel.

Key Components of a Successful Chemical Inventory System

A successful chemical inventory system encompasses several critical components, each designed to enhance safety, efficiency, and compliance. These components work in harmony to create a robust and reliable inventory management framework.

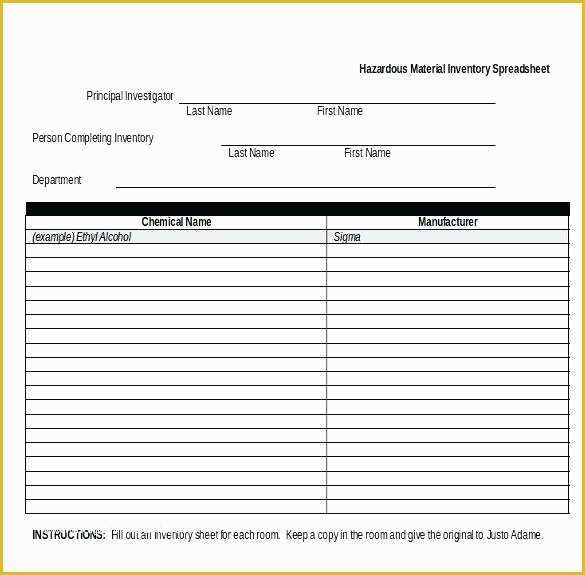

Accurate Record-Keeping

At the core of any effective chemical inventory system is accurate record-keeping. This involves maintaining detailed and up-to-date records of all chemicals in the inventory, including their quantities, locations, and relevant safety information. By keeping precise records, organizations can quickly identify potential hazards, track usage trends, and ensure compliance with regulatory requirements.

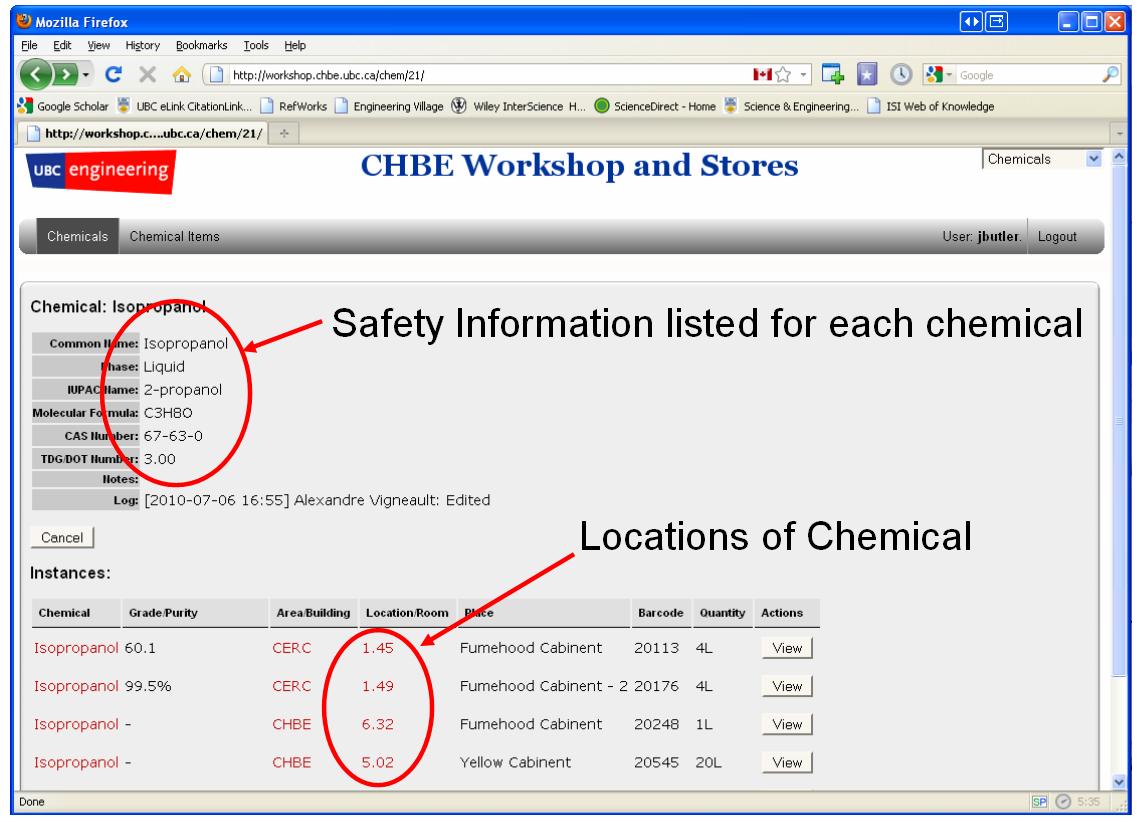

Advanced inventory management software plays a pivotal role in streamlining this process. These software solutions offer robust features such as barcoding, RFID tagging, and cloud-based data storage, making it easier to track and manage chemical inventories. Additionally, they often provide real-time updates and automated alerts, ensuring that inventory managers are always aware of any changes or discrepancies.

Safe Storage Practices

Proper storage of chemicals is essential to prevent accidents and maintain a safe working environment. This involves segregating incompatible chemicals, ensuring proper ventilation, and maintaining a controlled temperature and humidity level. It's crucial to follow industry-specific guidelines and best practices to mitigate the risks associated with chemical storage.

Modern storage facilities are designed with safety in mind, incorporating features such as fire-resistant materials, spill containment systems, and automated monitoring devices. These facilities, when coupled with rigorous safety protocols, significantly reduce the likelihood of accidents and minimize the potential impact of any incidents that do occur.

Regular Audits and Reconciliations

Conducting regular audits and reconciliations is vital to maintaining the integrity of the chemical inventory. These processes involve cross-checking physical inventory levels with the recorded data, identifying discrepancies, and taking corrective actions. By regularly auditing the inventory, organizations can ensure that their records are accurate and up-to-date, allowing for better decision-making and compliance.

Automated inventory management systems can greatly simplify this process by providing real-time data and automated alerts for any anomalies. These systems can also generate detailed reports, making it easier to identify trends, track usage patterns, and plan for future chemical needs.

Implementing a Robust Chemical Inventory Management System

Implementing a robust chemical inventory management system requires a strategic approach and careful consideration of various factors. Here are some key steps to guide you through the process:

Define Your Inventory Needs

Begin by clearly defining your organization's chemical inventory needs. Consider factors such as the types and quantities of chemicals used, storage requirements, and regulatory obligations. This step will help you determine the scale and complexity of your inventory management system.

It's essential to involve key stakeholders, including laboratory managers, safety officers, and procurement specialists, to gather a comprehensive understanding of the organization's chemical usage and requirements.

Choose the Right Inventory Management Software

Selecting the appropriate inventory management software is crucial for the success of your chemical inventory system. Look for software that offers features tailored to your specific needs, such as chemical-specific safety data, automated alerts, and integration with other laboratory systems.

Consider factors like ease of use, scalability, and compatibility with existing infrastructure. It's also beneficial to choose software that provides regular updates and has a strong support system to address any issues that may arise.

Develop a Comprehensive Training Program

Effective chemical inventory management relies on the knowledge and skills of your personnel. Develop a comprehensive training program to educate your staff on the importance of accurate inventory tracking, proper storage practices, and the use of the chosen inventory management software.

Training should cover topics such as chemical safety, handling procedures, and the proper recording of inventory data. Regular refresher courses and updates can help ensure that your staff remains proficient and aware of any changes or improvements to the system.

Implement a Clear Chemical Labeling System

A clear and consistent chemical labeling system is essential for quick identification and accurate tracking of chemicals. Implement a standardized labeling system that includes critical information such as the chemical name, concentration, storage instructions, and any potential hazards.

Consider using color-coding or symbols to quickly identify the nature of the chemical, especially for hazardous substances. This visual system can greatly improve safety and efficiency, especially in emergency situations.

Real-World Examples and Success Stories

Implementing a robust chemical inventory management system has proven successful for numerous organizations, leading to improved safety, efficiency, and compliance. Here are some real-world examples to illustrate the impact of effective chemical inventory practices.

Case Study: ABC Research Institute

ABC Research Institute, a leading biotechnology research facility, faced challenges with chemical inventory management due to the vast array of substances used in their research. By implementing a comprehensive inventory management system, they achieved remarkable results.

Through the use of advanced inventory software and rigorous training, ABC Research Institute reduced chemical waste by 30%, saving significant costs and minimizing environmental impact. The system's automated alerts and real-time data enabled swift response to potential hazards, enhancing safety and compliance. Additionally, the streamlined inventory process improved research efficiency, leading to faster time-to-market for their innovative products.

Success Story: XYZ Manufacturing Company

XYZ Manufacturing Company, a large-scale industrial producer, had a history of chemical inventory management issues, leading to frequent compliance violations and safety concerns. However, with a dedicated focus on improving their inventory practices, they achieved notable success.

By implementing a robust chemical inventory system, XYZ Manufacturing Company achieved a 95% accuracy rate in their chemical inventory records, ensuring strict compliance with environmental and safety regulations. The system's advanced storage management features allowed for better organization and segregation of chemicals, reducing the risk of accidents. Furthermore, the company's investment in employee training paid dividends, as staff became more aware of the importance of accurate inventory tracking and safe chemical handling practices.

Future Implications and Technological Advances

The field of chemical inventory management is constantly evolving, driven by technological advancements and changing regulatory landscapes. Here's a glimpse into the future of chemical inventory management and the potential implications for your organization.

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are poised to revolutionize chemical inventory management. These technologies can analyze vast amounts of data, identify patterns, and make predictions, enabling more efficient inventory planning and management.

AI-powered systems can optimize chemical usage, predict future needs, and suggest cost-saving measures. ML algorithms can also enhance safety by identifying potential hazards and providing real-time alerts, helping organizations stay ahead of potential issues.

Cloud-Based Inventory Management

Cloud-based inventory management systems are gaining traction, offering numerous benefits such as real-time data access, scalability, and enhanced security. These systems allow multiple users to access and update inventory data simultaneously, improving collaboration and efficiency.

With cloud-based systems, organizations can easily integrate their chemical inventory management with other business processes, such as procurement and accounting, leading to better data analysis and decision-making.

Regulatory Changes and Compliance

Regulatory bodies are continuously updating and tightening chemical regulations to ensure public safety and environmental protection. Staying abreast of these changes is crucial for maintaining compliance and avoiding penalties.

Advanced inventory management systems can assist in this regard by providing automated updates on regulatory changes and offering tools to help organizations adapt their practices accordingly. These systems can also generate detailed reports and documentation, making it easier to demonstrate compliance during audits or inspections.

FAQs

What are the key benefits of effective chemical inventory management?

+

Effective chemical inventory management offers several key benefits, including enhanced safety, regulatory compliance, optimized resource allocation, improved research efficiency, and better emergency response planning.

How often should chemical inventories be audited and reconciled?

+

Regular audits and reconciliations are crucial for maintaining accurate chemical inventories. The frequency of these audits can vary depending on the organization’s needs and the complexity of their inventory. However, as a general guideline, quarterly audits are recommended to ensure ongoing accuracy and compliance.

What are some best practices for safe chemical storage?

+

Safe chemical storage involves several best practices, including proper segregation of incompatible chemicals, ensuring adequate ventilation, maintaining controlled temperature and humidity levels, and implementing spill containment measures. It’s crucial to follow industry-specific guidelines and regularly inspect storage facilities for any potential hazards.

How can organizations choose the right inventory management software for their needs?

+

When selecting inventory management software, organizations should consider factors such as the software’s compatibility with existing systems, ease of use, scalability, and the level of support provided by the software vendor. It’s also beneficial to evaluate the software’s features, ensuring they align with the organization’s specific chemical inventory management requirements.

What role does training play in effective chemical inventory management?

+

Training is a critical component of effective chemical inventory management. By educating staff on the importance of accurate inventory tracking, safe chemical handling practices, and the use of inventory management software, organizations can ensure that their personnel are equipped with the knowledge and skills necessary to maintain a safe and compliant chemical inventory.