Hazard Warning Label

The importance of hazard warning labels cannot be overstated in ensuring workplace safety and compliance with regulations. These labels serve as vital communication tools, providing crucial information about potential risks and hazards associated with various substances, equipment, or environments. In this comprehensive guide, we will delve into the world of hazard warning labels, exploring their purpose, types, design considerations, and their critical role in promoting a safer working environment.

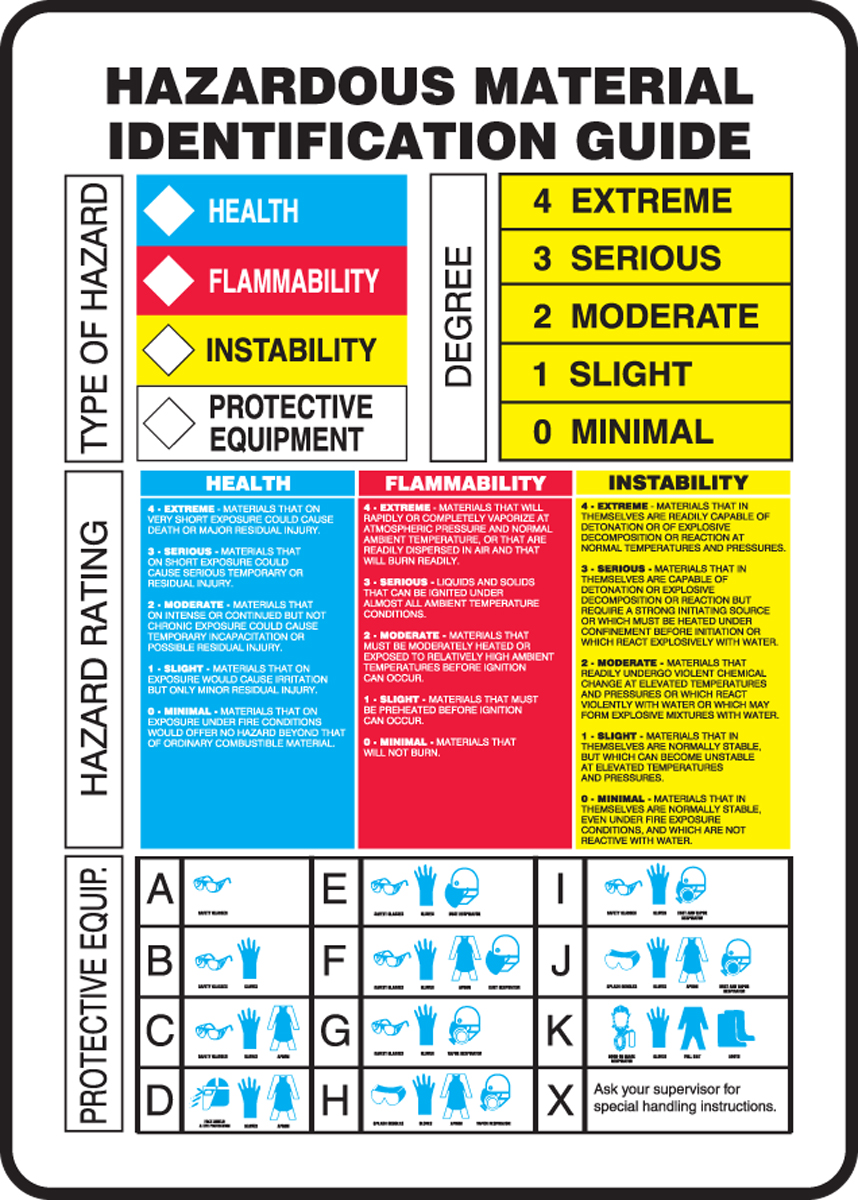

Understanding Hazard Warning Labels

Hazard warning labels are a critical component of occupational safety and health programs. They are designed to inform and protect individuals from potential hazards and risks in the workplace. These labels are a form of visual communication, using a combination of text, symbols, and colors to convey important safety information.

The primary purpose of hazard warning labels is to prevent accidents, injuries, and illnesses by alerting individuals to potential dangers. By providing clear and concise information, these labels enable workers to make informed decisions and take appropriate precautions. Whether it's identifying flammable substances, indicating the presence of high voltage, or warning about toxic materials, hazard warning labels play a pivotal role in maintaining a safe and healthy work environment.

Types of Hazard Warning Labels

Hazard warning labels come in various forms, each designed to address specific types of hazards. Here are some common types of hazard warning labels:

Flammable and Combustible Materials Labels

These labels are used to identify substances that can easily catch fire and burn. They typically feature a red background with a flame symbol and text warning about the flammability of the material. Flammable labels are crucial in preventing fires and ensuring proper handling and storage of flammable substances.

Toxic and Hazardous Chemical Labels

Labels for toxic and hazardous chemicals are designed to alert individuals to the presence of substances that can cause harm or injury. These labels often use a skull and crossbones symbol, accompanied by text describing the specific hazards associated with the chemical. Proper labeling of toxic substances is essential for the safe handling, storage, and disposal of these materials.

Electrical Hazard Labels

Electrical hazard labels are used to warn about the presence of electrical equipment or areas with high voltage. They typically feature a yellow background with a lightning bolt symbol and text indicating the potential for electrical shock or other electrical hazards. These labels are critical in preventing electrical accidents and ensuring proper safety measures are in place.

Biological Hazard Labels

Biological hazard labels, often referred to as biohazard labels, are used to identify materials or areas that pose a risk of infection or contamination. These labels typically have a fluorescent orange or lime-green background with a biohazard symbol. They are commonly found in laboratories, medical facilities, and areas where biological samples are handled.

Radiation Hazard Labels

Radiation hazard labels are used to warn about the presence of radioactive materials or areas with high radiation levels. These labels often feature a bright yellow or magenta background with a radiation trefoil symbol. They are essential in preventing exposure to harmful radiation and ensuring the safe handling and storage of radioactive substances.

Design Considerations for Effective Hazard Warning Labels

Creating effective hazard warning labels requires careful consideration of several factors. Here are some key design elements to ensure the labels are clear, noticeable, and informative:

Color and Contrast

The use of high-contrast colors is crucial in making hazard warning labels easily visible. Common color combinations include red and white for flammability, yellow and black for electrical hazards, and orange or lime-green for biological hazards. These colors are chosen to stand out and draw attention, ensuring that the labels are noticed even in busy environments.

Symbol and Iconography

Symbols and icons play a vital role in hazard warning labels, as they can quickly convey important information. Standardized symbols, such as the flame symbol for flammability or the biohazard symbol, are universally recognized and understood. Including these symbols alongside text enhances the effectiveness of the label and ensures a quick understanding of the potential hazards.

Text and Language

The text on hazard warning labels should be clear, concise, and easy to understand. Avoid using technical jargon or complex language that may confuse workers. Instead, use simple and direct language to convey the specific hazard and any necessary precautions. It’s also important to consider the language used, ensuring that the labels are accessible to all workers, regardless of their primary language.

Size and Placement

The size of hazard warning labels should be appropriate for the intended viewing distance. Larger labels are needed for areas where the label may be viewed from a distance, while smaller labels can be used for more intimate spaces. Proper placement is crucial, ensuring that the labels are positioned where they are most likely to be seen and where the associated hazard is present.

Durability and Weather Resistance

Hazard warning labels must be durable and able to withstand various environmental conditions. Labels used outdoors or in harsh environments should be weather-resistant and able to withstand exposure to moisture, sunlight, and extreme temperatures. This ensures that the labels remain visible and effective over time, even in challenging conditions.

Compliance with Regulations

Hazard warning labels are subject to various regulations and standards to ensure consistency and effectiveness. In many countries, including the United States, hazard warning labels must adhere to specific guidelines set by regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). These regulations dictate the use of specific colors, symbols, and wording to ensure uniformity and compliance.

Adhering to these regulations is crucial to avoid legal consequences and to ensure that workers receive consistent and accurate information about potential hazards. Failure to comply with labeling requirements can result in fines, penalties, and, most importantly, increased risks to worker safety.

Implementing and Maintaining Hazard Warning Labels

Effective implementation of hazard warning labels involves more than just placing labels on equipment or containers. It requires a comprehensive approach that includes training workers on the meaning and importance of the labels, as well as regular audits and inspections to ensure the labels remain accurate and up-to-date.

Regular inspections should be conducted to identify any changes in hazards or the need for additional labels. As new substances, equipment, or processes are introduced, the hazard warning labels must be reviewed and updated accordingly. This ongoing maintenance ensures that the labels remain relevant and provide accurate information to workers.

Future Trends and Innovations

The field of hazard warning labels is continuously evolving, with advancements in technology and a growing focus on worker safety. Here are some future trends and innovations to watch out for:

Digital Hazard Warning Labels

With the increasing use of digital technologies, there is a growing trend towards digital hazard warning labels. These labels can be displayed on digital screens or mobile devices, providing real-time information about potential hazards. Digital labels can be easily updated and offer interactive features, such as providing additional details or instructions when needed.

Augmented Reality (AR) Labels

Augmented reality technology is being explored to enhance the effectiveness of hazard warning labels. AR labels can provide workers with an overlay of information when viewing a hazardous area or equipment through a mobile device or AR headset. This technology can offer detailed instructions, safety procedures, and even virtual training simulations to enhance worker understanding and safety.

Smart Hazard Warning Systems

The development of smart hazard warning systems is another exciting innovation. These systems use sensors and advanced algorithms to detect potential hazards and automatically trigger the appropriate warning labels. By integrating sensors with hazard warning labels, these systems can provide real-time alerts and ensure a more responsive and dynamic safety approach.

Conclusion

Hazard warning labels are a critical component of workplace safety, serving as a visual reminder of potential hazards and risks. By understanding the different types of labels, their design considerations, and the importance of compliance and maintenance, organizations can create a safer work environment for their employees. As technology advances, the future of hazard warning labels looks promising, with digital, AR, and smart systems offering enhanced safety and improved worker understanding.

What are the key elements of an effective hazard warning label?

+

An effective hazard warning label should include a combination of elements such as high-contrast colors, standardized symbols, clear and concise text, appropriate size and placement, and durability to withstand various environmental conditions. These elements work together to ensure the label is easily visible, understandable, and able to withstand the intended environment.

Are there international standards for hazard warning labels?

+

Yes, there are international standards and guidelines for hazard warning labels. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a unified approach to classifying and communicating chemical hazards. Additionally, organizations such as the International Organization for Standardization (ISO) have developed standards for hazard warning labels to ensure consistency and effectiveness across different countries.

How often should hazard warning labels be reviewed and updated?

+

Hazard warning labels should be reviewed and updated regularly, especially when there are changes in the workplace, new substances or equipment are introduced, or if there are updates to relevant regulations or standards. It is recommended to conduct periodic audits and inspections to ensure the labels remain accurate and up-to-date, typically at least once a year.