Personal Protective Wear

In today's world, personal protective wear has become an essential part of our daily lives, especially in light of recent global health crises. From healthcare professionals on the front lines to individuals navigating public spaces, protective gear plays a crucial role in ensuring safety and well-being. This comprehensive guide aims to delve into the world of personal protective wear, exploring its various types, advancements, and their impact on different industries.

The Evolution of Personal Protective Wear

The concept of protective wear has evolved significantly over the years, driven by advancements in technology and a growing awareness of occupational hazards. Historically, protective gear was often basic and designed to mitigate physical risks such as sharp objects or heavy machinery. However, the modern landscape of personal protective wear is far more complex and multifaceted.

Today, personal protective equipment (PPE) encompasses a wide range of garments and accessories designed to protect individuals from a myriad of hazards, including biological agents, chemical substances, radiation, and even extreme weather conditions. The global market for PPE is estimated to reach USD 75.2 billion by 2026, driven by rising health and safety concerns across various industries.

Key Milestones in PPE Development

-

Early 20th Century: The advent of industrial safety regulations led to the development of protective gear for miners, construction workers, and factory employees. This included hard hats, safety goggles, and protective clothing.

-

1930s: With the rise of chemical industries, the need for chemical-resistant PPE became apparent. This era saw the introduction of rubber gloves and suits, offering protection against hazardous substances.

-

1980s: The HIV/AIDS epidemic brought attention to the importance of biological protection. This period witnessed the widespread adoption of disposable gloves, gowns, and face masks in healthcare settings.

-

2010s: Technological advancements led to the development of smart PPE, incorporating sensors and communication technologies. These innovations enhance safety monitoring and emergency response capabilities.

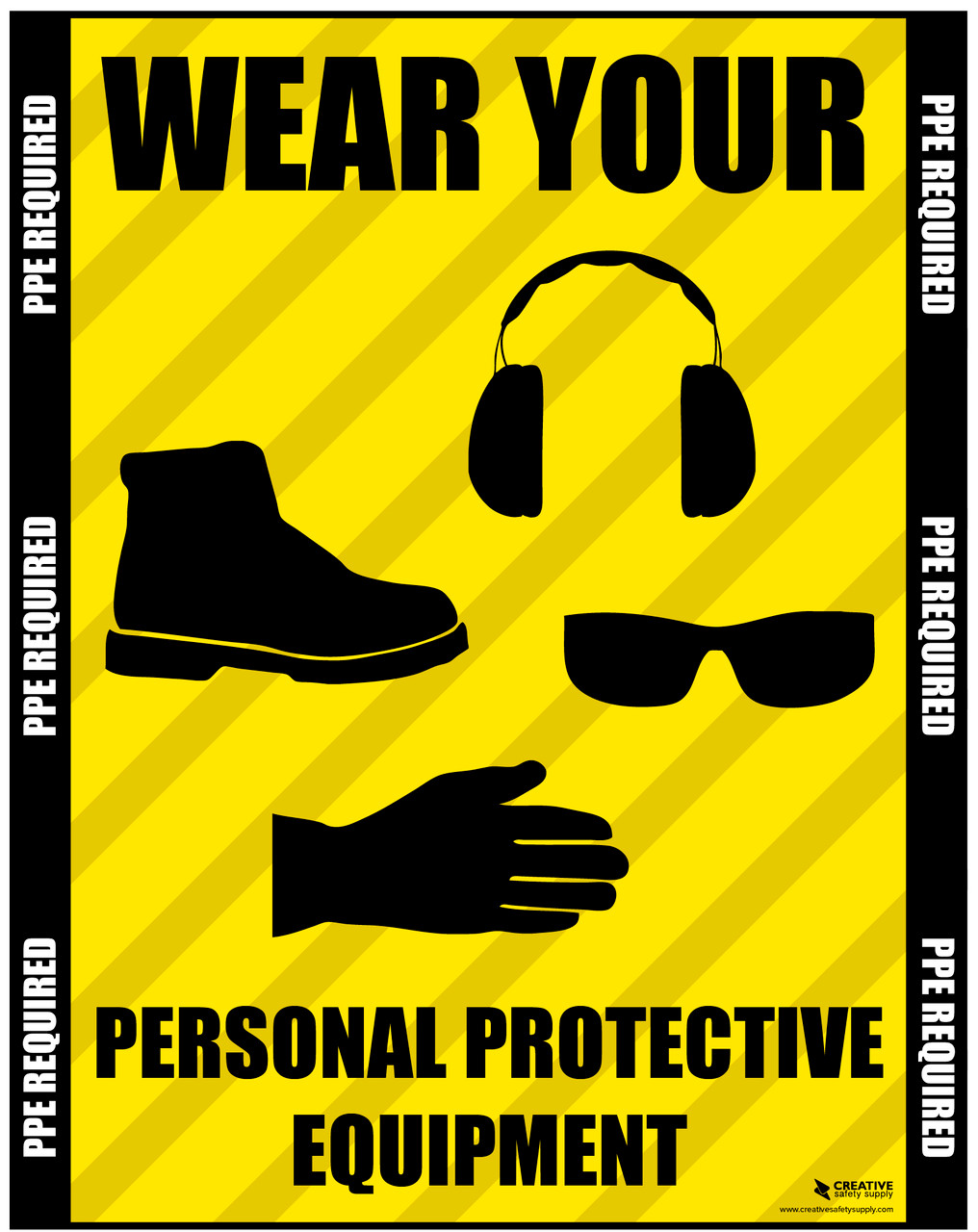

Types of Personal Protective Wear

Personal protective wear can be categorized into several types, each designed to address specific hazards and industries. Here’s an overview of the most common types of PPE:

Respiratory Protection

Respiratory protection is vital in environments where airborne contaminants pose a risk. This category includes:

- Face Masks: Ranging from simple surgical masks to N95 respirators, these protect against particles, droplets, and aerosols.

- Respirators: Powered Air-Purifying Respirators (PAPRs) and Self-Contained Breathing Apparatus (SCBA) provide protection in hazardous environments with limited oxygen.

Eye and Face Protection

Eye and face protection is essential in industries such as construction, manufacturing, and laboratories. Some key items include:

- Safety Goggles: These protect against flying debris, chemicals, and impact hazards.

- Face Shields: Offering full-face protection, face shields are commonly used in medical procedures and chemical handling.

Head Protection

Head protection is critical in industries with a risk of head injuries. The main types include:

- Hard Hats: Worn by construction workers and miners, hard hats provide protection against falling objects and electrical hazards.

- Bump Caps: Lightweight headgear designed to protect against minor bumps and scrapes.

Hand and Arm Protection

Hand and arm protection is vital in various industries, from healthcare to manufacturing. Key items include:

- Gloves: A wide range of gloves, from disposable nitrile gloves to heavy-duty leather gloves, offer protection against chemicals, sharp objects, and extreme temperatures.

- Arm Guards: Used in woodworking and metalworking, arm guards protect against cuts and burns.

Foot and Leg Protection

Foot and leg protection is crucial in industries where there’s a risk of heavy objects falling or sharp objects penetrating. Common PPE includes:

- Safety Shoes: Steel-toe boots and shoes provide protection against heavy objects and electrical hazards.

- Leg Guards: Used in forestry and construction, leg guards protect against chainsaw injuries and sharp objects.

Advancements in Personal Protective Wear

The field of personal protective wear is constantly evolving, driven by technological innovations and an increasing focus on worker safety. Here are some key advancements:

Smart PPE

Smart PPE incorporates sensors, communication technologies, and data analytics to enhance safety and improve worker well-being. These innovations can monitor vital signs, detect hazardous conditions, and provide real-time alerts. For instance, smart helmets can detect falls and alert emergency services, while smart gloves can provide haptic feedback for improved precision.

Nanotechnology

Nanotechnology is being used to develop lightweight, breathable, and highly protective materials. Nanofibers, for example, can be used to create protective garments that offer enhanced chemical and biological protection without compromising comfort.

3D Printing

3D printing technology is revolutionizing the production of personalized protective gear. This technology enables the creation of custom-fit items, ensuring optimal comfort and protection for individual workers. It also allows for rapid prototyping and the development of specialized PPE for niche industries.

The Impact on Industries

Personal protective wear has a profound impact on various industries, shaping work environments and safety standards. Here’s how PPE influences key sectors:

Healthcare

In the healthcare industry, PPE is vital for protecting healthcare workers and preventing the spread of infections. Surgical masks, gloves, and gowns are standard equipment in hospitals and clinics. With the rise of pandemics, the demand for advanced respiratory protection and full-body suits has increased significantly.

Construction

Construction sites are high-risk environments, and PPE plays a critical role in mitigating hazards. Hard hats, safety goggles, and high-visibility clothing are essential for protecting workers from falling objects, electrical hazards, and vehicle collisions.

Manufacturing

Manufacturing processes often involve exposure to chemicals, extreme temperatures, and moving machinery. PPE in this industry includes chemical-resistant suits, heat-resistant gloves, and ear protection for noisy environments. The rise of Industry 4.0 has also led to the development of smart PPE for remote monitoring and emergency response.

Agriculture

Agricultural workers face unique hazards, including exposure to pesticides, extreme weather conditions, and sharp tools. PPE in agriculture includes respirators, protective clothing, and safety boots. As precision agriculture gains traction, the demand for smart PPE to monitor worker health and safety is on the rise.

The Future of Personal Protective Wear

As we look towards the future, personal protective wear is poised to become even more advanced and integrated into our daily lives. Here are some potential developments:

-

Wearable Technology: The integration of wearable technology into PPE will enable real-time health monitoring, hazard detection, and improved communication. This could include smart fabrics that change color to indicate exposure to hazardous substances.

-

Biodegradable Materials: With a growing focus on sustainability, the development of biodegradable PPE materials is on the horizon. This would reduce the environmental impact of disposable gear.

-

Augmented Reality: AR-integrated PPE could provide workers with real-time visual cues and information, enhancing safety and productivity. For instance, AR goggles could display hazardous areas or provide step-by-step instructions for complex tasks.

Frequently Asked Questions

What are the key considerations when choosing personal protective wear?

+

When selecting PPE, it’s crucial to consider the specific hazards present in your work environment. Different types of PPE are designed to protect against various risks, so it’s essential to match the equipment to the task. Comfort and fit are also important factors, as ill-fitting PPE can reduce effectiveness and compliance.

How often should personal protective wear be replaced or refurbished?

+

The replacement frequency of PPE depends on various factors, including the type of equipment, its usage, and the hazards it’s exposed to. Some items, like disposable masks, are designed for single-use, while others, like hard hats, can be refurbished and reused if they meet safety standards and show no signs of damage.

Are there any regulations governing the use of personal protective wear?

+

Yes, many countries have regulations and standards in place to ensure the effectiveness and proper use of PPE. These regulations often specify the types of PPE required for specific industries and tasks, as well as the frequency of inspections and training.

How can employers ensure their workers are properly trained in the use of personal protective wear?

+

Employers should provide comprehensive training programs that cover the proper use, maintenance, and limitations of PPE. This training should be conducted regularly and tailored to the specific needs of the workforce. Additionally, regular inspections and audits can help ensure compliance and identify areas for improvement.

What are the key benefits of investing in high-quality personal protective wear?

+

Investing in high-quality PPE offers several benefits. Firstly, it ensures optimal protection for workers, reducing the risk of injuries and illnesses. High-quality PPE is also more durable and comfortable, leading to increased compliance and productivity. Additionally, it can reduce long-term costs associated with workplace accidents and injuries.