The Ultimate Guide to Silo Structures

Welcome to the ultimate guide on silo structures, a comprehensive resource designed to provide you with an in-depth understanding of these iconic storage systems. From their historical origins to modern-day applications, we'll explore the world of silos, uncovering their design, functionality, and the vital role they play in various industries. Get ready to dive into the fascinating world of silo structures and discover the secrets behind their enduring popularity.

A Brief History of Silo Structures

Silo structures have a rich historical background that dates back centuries. The concept of storing grains and other agricultural products in elevated, cylindrical structures can be traced to ancient civilizations. Early silos were often made from stone or clay and served as a crucial means of preserving surplus crops for times of scarcity.

The word "silo" itself has an interesting origin. Derived from the Spanish word "silos," meaning "storehouse" or "granary," it reflects the early association of silos with agricultural storage. These early silos were typically built into the ground, utilizing the natural cooling properties of the earth to maintain the freshness of stored goods.

However, it was during the late 19th and early 20th centuries that silo structures underwent significant evolution. The advent of modern farming practices and the increasing demand for efficient storage solutions led to the development of taller, more robust silos. This period saw the widespread adoption of metal silos, particularly in the United States, where they became a symbol of agricultural progress and modernization.

The iconic cylindrical shape of silos, with their distinctive conical roofs, emerged as a result of practical considerations. The circular design allows for even distribution of weight, making silos structurally sound and capable of withstanding the pressures of large volumes of stored material. Additionally, the smooth interior surfaces facilitate the easy flow of grains, enhancing the efficiency of loading and unloading processes.

Types of Silo Structures

Silo structures come in various forms, each tailored to specific storage needs and applications. Understanding the different types is essential for choosing the right silo system for your requirements.

Metal Silos

Metal silos, particularly those made from steel, are among the most common types. They offer exceptional durability and can withstand harsh weather conditions, making them ideal for outdoor storage. Steel silos are widely used in the agricultural sector for storing grains, as well as in industries such as cement and chemical manufacturing.

| Type | Description |

|---|---|

| Welded Steel Silos | Constructed by welding steel plates, these silos provide excellent strength and are suitable for storing large volumes of grains and other bulk materials. |

| Bolted Steel Silos | Assembled using bolted connections, these silos offer flexibility in terms of transportation and on-site construction. They are often used in remote locations or for temporary storage solutions. |

Concrete Silos

Concrete silos, also known as reinforced concrete silos, are another popular choice. They are highly durable and provide excellent resistance to environmental factors such as moisture and temperature fluctuations. Concrete silos are commonly used for long-term storage of grains, cement, and other materials.

Wooden Silos

Wooden silos, while less common today, have a rich history in certain regions. Historically, wooden silos were widely used in the 19th and early 20th centuries, particularly in areas where timber was abundant. While they may not be as durable as metal or concrete silos, wooden silos have a unique aesthetic appeal and are sometimes used for historical preservation or as decorative elements.

Specialized Silos

Beyond the traditional agricultural silos, specialized silos have emerged to meet the unique needs of various industries. These include:

- Fly Ash Silos: Used in the power generation industry to store fly ash, a by-product of coal combustion.

- Feed Silos: Designed for storing animal feed, these silos often incorporate features like automatic feeding systems.

- Lime Silos: Employed in the construction industry for storing lime, an essential material in various applications.

- Grain Legumes Silos: Tailored for the storage of grain legumes like soybeans and lentils, these silos are equipped with specialized cleaning and sorting systems.

Design and Construction of Silo Structures

The design and construction of silo structures are governed by a set of principles aimed at ensuring structural integrity, safety, and efficiency. Here’s an overview of the key considerations in the silo design and construction process.

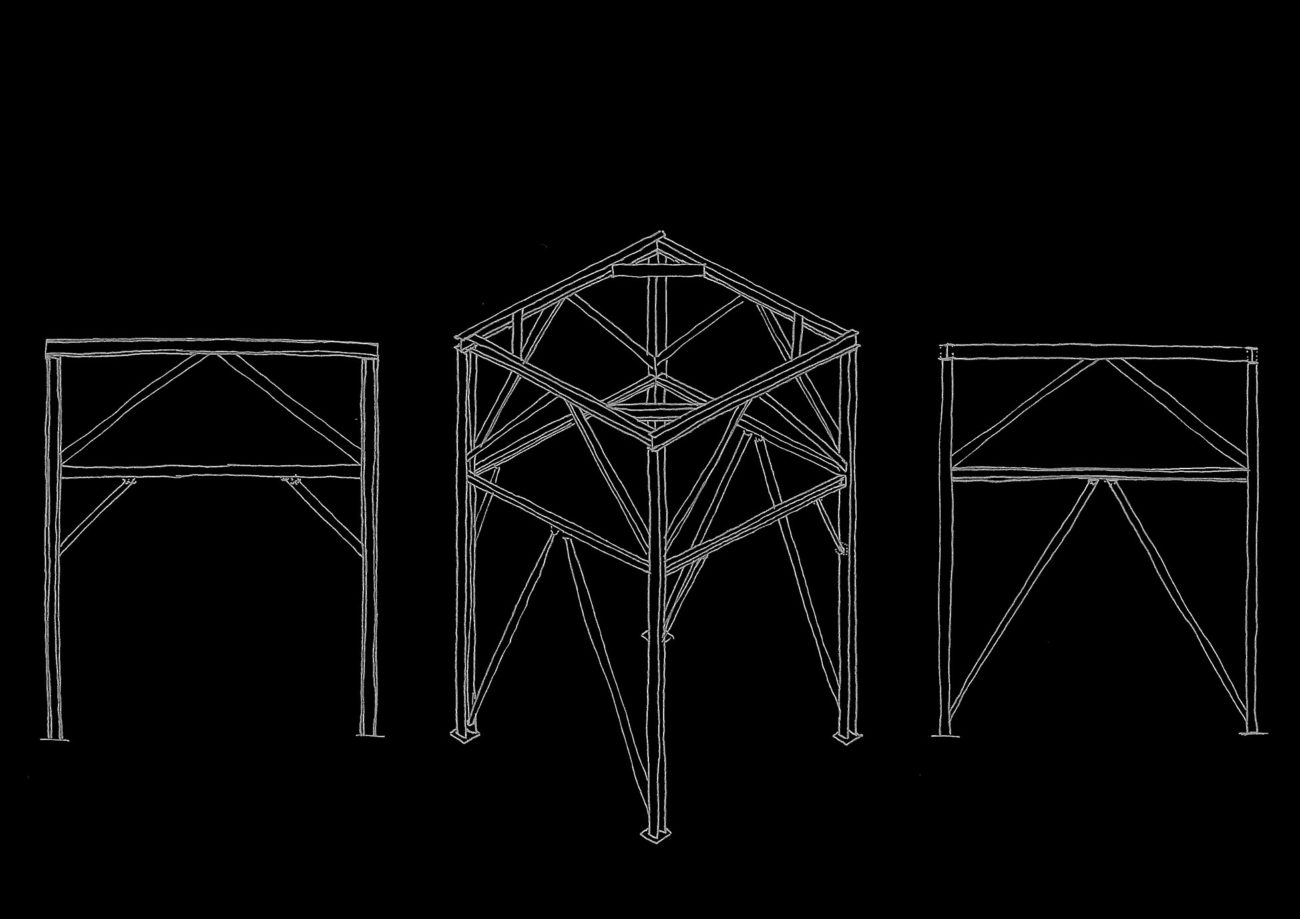

Structural Design

Silo structures are designed to withstand the weight of the stored material and external forces such as wind and earthquakes. The structural design involves calculating load distributions, considering the material properties, and selecting appropriate construction materials. Engineers use advanced software and modeling techniques to ensure the silo can withstand the pressures of its intended use.

Foundation and Base Construction

A solid foundation is crucial for the stability of silo structures. The base construction involves preparing a level surface and ensuring proper drainage to prevent moisture-related issues. For metal silos, the foundation may include a concrete base or a specialized metal frame. In the case of concrete silos, the base is an integral part of the structure and requires careful reinforcement to support the weight of the silo and its contents.

Material Handling Systems

Efficient material handling is a critical aspect of silo design. The system typically includes loading and unloading mechanisms, such as conveyors, augers, or pneumatic systems. These systems must be designed to ensure smooth and safe movement of materials into and out of the silo. Proper material handling not only enhances operational efficiency but also reduces the risk of contamination or damage to the stored goods.

Safety Features

Safety is a paramount concern in silo design. Silos are equipped with various safety features to prevent accidents and ensure the well-being of personnel. These features may include:

- Ventilation Systems: Proper ventilation is essential to prevent the buildup of hazardous gases, especially in silos storing flammable materials.

- Emergency Exits and Access Points: Silo structures should have well-designed access points for maintenance and inspection, as well as emergency exits for rapid evacuation in case of emergencies.

- Fire Protection Systems: Fire suppression systems, such as sprinklers or foam generators, are crucial for protecting silos from fire hazards.

- Level Indicators and Monitoring Systems: These systems provide real-time data on the level of stored material, helping operators maintain optimal storage conditions and prevent overloading.

Applications and Industries

Silo structures find applications across a wide range of industries, each with its unique storage requirements. Let’s explore some of the key industries where silos play a vital role.

Agriculture and Food Production

The agricultural sector is perhaps the most well-known user of silo structures. Silos are widely employed for the storage of grains, such as wheat, corn, and rice. They provide a controlled environment, protecting crops from pests, moisture, and temperature fluctuations. Silos also facilitate the efficient handling and distribution of grains, ensuring a steady supply for food production and animal feed.

Cement and Construction Industries

In the cement industry, silos are essential for storing and handling cement powder. These silos must be designed to withstand the abrasive nature of cement and ensure a consistent flow of material. Silos are also used in the construction industry for storing various materials, including sand, aggregates, and even finished products like concrete blocks.

Chemical and Pharmaceutical Industries

Silos play a crucial role in the chemical and pharmaceutical sectors, where they are used to store a wide range of materials, from raw chemicals to finished products. The specialized design of these silos ensures the safe and controlled storage of potentially hazardous substances. Silos in these industries are often equipped with advanced monitoring systems to maintain optimal storage conditions and prevent contamination.

Energy Sector

Silos have found applications in the energy sector, particularly in the storage of biofuels and other renewable energy sources. For instance, silos are used to store biomass materials like wood chips and agricultural waste, which can be converted into biofuels. Additionally, silos are employed in the storage of compressed air, a key component in certain renewable energy systems.

Maintenance and Safety Considerations

Maintaining silo structures is crucial for ensuring their longevity and operational efficiency. Regular maintenance not only extends the life of the silo but also prevents potential hazards and safety issues.

Routine Inspections

Routine inspections are an essential part of silo maintenance. These inspections involve checking the structural integrity, identifying any signs of corrosion or damage, and ensuring that all safety features are functioning properly. Regular inspections help catch potential issues early on, allowing for timely repairs and preventing major failures.

Cleaning and Sanitation

Cleaning and sanitizing silo interiors are critical for maintaining product quality and preventing contamination. Depending on the stored material, different cleaning methods may be employed. For instance, silos used for food storage require thorough cleaning and disinfection to meet food safety standards. Specialized cleaning equipment, such as silo sweepers and vacuum systems, is often used to ensure a clean and hygienic environment.

Corrosion Prevention

Corrosion is a significant concern in silo structures, particularly in metal silos. To prevent corrosion, proper surface preparation and the application of protective coatings are essential. Regular inspections and maintenance of the coating system help ensure the long-term integrity of the silo.

Safety Training and Protocols

Ensuring the safety of personnel working with silo structures is of utmost importance. Comprehensive safety training programs should be implemented to educate workers about potential hazards, proper operating procedures, and emergency response protocols. Regular safety drills and the establishment of clear communication channels further enhance safety measures.

Future Trends and Innovations

The world of silo structures is constantly evolving, with ongoing research and development leading to new innovations and advancements. Here’s a glimpse into the future of silo technology.

Smart Silos

The integration of advanced technologies is transforming traditional silos into smart storage systems. Smart silos are equipped with sensors and IoT (Internet of Things) devices, enabling real-time monitoring of storage conditions. These silos can provide data on temperature, humidity, and material levels, allowing for remote management and optimized storage practices.

Automated Material Handling

Advancements in automation are revolutionizing material handling processes in silos. Automated systems, such as robotic arms and conveyor systems, enhance efficiency and reduce the need for manual labor. These systems can precisely control the flow of materials, ensuring accurate dosing and minimizing waste.

Sustainable Silo Design

Sustainability is a growing concern across industries, and silo structures are no exception. Future silo designs are likely to incorporate eco-friendly materials and construction practices. Additionally, the development of energy-efficient cooling and ventilation systems will reduce the environmental impact of silo operations.

Specialized Silos for New Applications

As new industries emerge and existing industries evolve, specialized silos will continue to be developed to meet unique storage requirements. From storing advanced materials for the aerospace industry to accommodating the storage needs of emerging technologies, silo structures will adapt to the changing landscape of modern industries.

Conclusion

Silo structures have stood the test of time, evolving from ancient storehouses to sophisticated storage systems integral to modern industries. Their versatility, durability, and efficiency make them an indispensable part of global supply chains. As we’ve explored in this guide, silos come in various forms, each designed to meet specific storage needs. From the agricultural fields to cutting-edge industries, silos continue to play a vital role in ensuring the smooth flow of materials and the prosperity of societies.

What are the key advantages of using silo structures in the agricultural sector?

+Silo structures offer several advantages in agriculture. They provide a controlled environment for grain storage, protecting crops from pests and moisture. Silos also facilitate efficient handling and distribution, ensuring a steady supply of grains for food production and animal feed. Additionally, silos can be designed to accommodate the unique needs of different crops, making them versatile storage solutions.

How do smart silos improve operational efficiency in industries?

+Smart silos, equipped with sensors and IoT technology, revolutionize storage management. These silos provide real-time data on storage conditions, allowing for remote monitoring and optimized storage practices. By tracking temperature, humidity, and material levels, smart silos enable industries to enhance operational efficiency, reduce waste, and improve overall productivity.

What are some common challenges in maintaining silo structures, and how can they be addressed?

+Common challenges in silo maintenance include corrosion, especially in metal silos, and the buildup of contaminants. To address these issues, regular inspections, proper surface preparation, and the application of protective coatings are essential. Additionally, implementing thorough cleaning and sanitation protocols ensures a clean and safe storage environment.